Chemistry professor Tricia Carmichael and her research team are creating light-emitting textiles by adding a thin film of gold to ultrasheer fabric.

Chemistry professor Tricia Carmichael and her research team are creating light-emitting textiles by adding a thin film of gold to ultrasheer fabric.

When researchers in Tricia Carmichael’s materials chemistry lab coat pantyhose in gold, it’s not out of extravagant fashion sense.

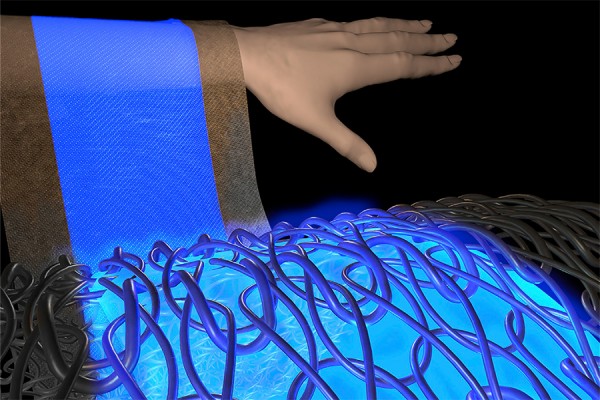

Dr. Carmichael and her UWindsor team are creating the next generation of light-emitting textiles by depositing a thin film of gold over ultrasheer fabric. The technique, featured in the cover article of the latest issue of Matter, may result in softer clothing for first responders and construction workers, more comfortable athletic apparel, and opens up new possibilities in wearable advertising.

“Users want light-emitting displays that are integrated into fabrics so that they are soft, lightweight, stretchable, washable, and wearable — just like ordinary clothing, but with light-emitting panels that can illuminate the user or display graphics or information,” said Carmichael.

Current approaches to making clothing that emits light involves sewing diodes, wires, and optical fibres into the fabric. Carmichael and her team instead immerse nylon and spandex fabric in a plating solution, a technique similar to that used to make printed circuit boards. The layer of gold deposited is ultrathin —1,000 times thinner than a human hair — allowing the fabric to retain its elasticity and sheerness while still being able to conduct electricity.

The chemical stability of gold and the fact it is hypoallergenic make it an excellent material for luminous clothing, said Carmichael. Cost isn’t a prohibitive factor since only a small amount of gold is used.

And, because the process uses existing fabrics, there’s no need to do research into new textiles.

Carmichael credits graduate student Yunyun Wu with coming up with the idea. She said Wu was out shopping for fabrics for her research and “had a eureka moment.” Wu, the lead author of the recently-published research paper, thought of using a sheer fabric as a transparent conductor.

“A second lightbulb moment came when we thought of pantyhose as an ideal material to build the new electrodes.”

So far, the team has been able to produce a luminous smiley-face emoji and an array of numbers that change on small squares of fabric. But Carmichael said she is optimistic about producing larger pieces.

“The process we use to deposit the ultrathin gold coating on fabric fibers can be scaled up by increasing the volume of the plating solution, enabling processing of entire articles of clothing.”

—Sarah Sacheli