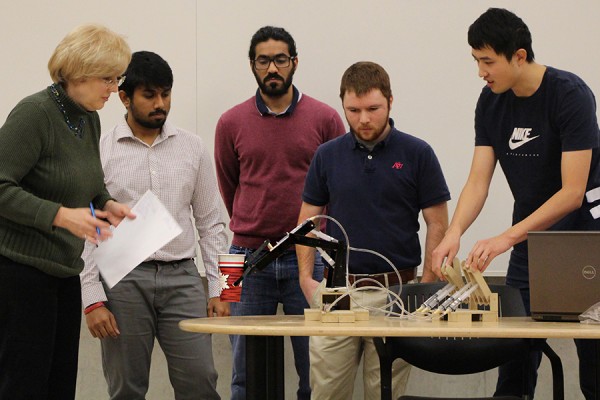

Professor Jill Urbanic looks on as students control a robotic arm to lift a paper cup during final project presentations Thursday in the Centre for Engineering Innovation.

Professor Jill Urbanic looks on as students control a robotic arm to lift a paper cup during final project presentations Thursday in the Centre for Engineering Innovation.

A project to design and build hydraulic robotic arms powered by syringes taught a class of engineering students about the challenges of the profession.

Teams demonstrated their creations for the third-year course “Manufacturing Process Design,” Thursday in the Centre for Engineering Innovation. Each project had to incorporate several joints and be able to grasp and lift an object, operated by rubber-piston needle syringes.

Designs incorporated wood and metal, dowels and glue, 3D-printed and molded plastics, employing fluids as different as oil and water to operate crab-like claws.

Designs incorporated wood and metal, dowels and glue, 3D-printed and molded plastics, employing fluids as different as oil and water to operate crab-like claws.

“We have some excellent projects,” said professor Jill Urbanic. “The students tried a lot of different approaches to the task.”

She noted that in their presentations, groups identified many of the same challenges.

“Friction, gears, material strength — any joint or seal is where failures will occur,” she said.

For their part, the students enjoyed showing off their solutions.

“In class we learn about different manufacturing systems,” said third-year industrial engineering major Jackie Ing. “Here we put them into practice in the shop, solving the problems of functionality.”

Her team fastened an electromagnet to the robot and demonstrated its ability to lift metal objects.

“I thought that was pretty innovative,” Ing said.