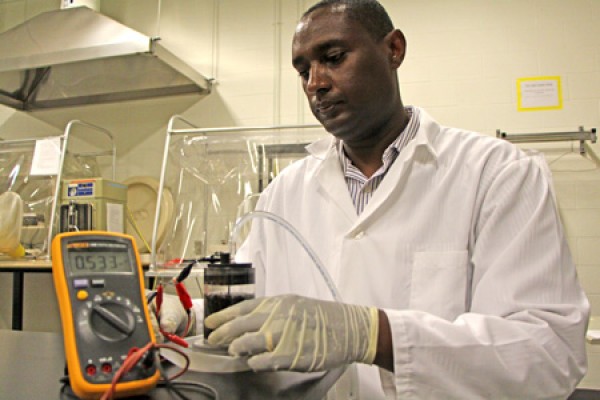

Wudneh Shewa measures the electrical current being produced by a microbial fuel cell in his lab in the Ed Lumley Centre for Engineering Innovation.

Wudneh Shewa measures the electrical current being produced by a microbial fuel cell in his lab in the Ed Lumley Centre for Engineering Innovation.

Manufacturers in the pulp and paper industry may one day convert a toxic by-product from their processes into electricity, thanks to the work of an engineering graduate student.

“Black liquor” is a dark liquid left over from the chemical process used to digest wood into paper pulp. Wudneh Shewa, a PhD student under the tutelage of Civil and Environmental Engineering professor Jerald Lalman, is developing a method of converting it into simple, non-toxic carbon compounds that can be converted into electricity using a microbial fuel cell.

“It’s like a battery,” said Shewa, who recently won a $1,000 scholarship for his work from the Water Environment Association of Ontario—a branch of the Water Environment Federation.

Shewa places simple carbon compounds produced from black liquor in a microbial fuel cell, which looks like a plastic jar with either a graphite brush or electrode inside, and is configured much in the same way as a solid state battery. Micro-organisms grow on the graphite surface in the anode compartment, and then feed on the carbon compounds, a process which produces electrons.

A cell with about 140 ml of liquid can produce more than half a volt of current. A standard AA battery produces 1.5 volts.

While it’s still a long ways from being put in to practice, Shewa hopes it’s a process pulp and paper manufacturers could scale up and use to generate enough electricity to power a portion of their operations. Most mills currently use recovery boilers to burn much of the black liquor they produce, generating steam, which produces electricity. However Shewa, who was a runner-up in the recent Three-Minute Thesis competition, believes the process he’s working on has potential to be a more efficient, greener and safer alternative.

“However, it’s difficult to suggest the technology we are proposing is an economically attractive option without conducting a detailed comparative technical and financial analysis,” he said.

Shewa, who submitted his thesis proposal in March and hopes to defend by next summer, said working on his project required a great deal of engineering knowledge, but also forced him to learn more about microbiology and electrochemistry.

“I had to work hard to understand all of these things,” said Shewa, who earned an undergraduate degree in sanitary engineering from Arba Minch University in Ethiopia and a master’s degree in environmental engineering from the Indian Institute of Technology at Roorkee. “This has taken two-and-a-half years of work.”

Watch a video of Shewa explaining his research at the Three-Minute Thesis competition.

.jpg)