Back to Lab Facilities

In combustion analysis, injection commands are often used as a reference to the start and end of injection to assist in analyzing the in-cylinder combustion process. However, the actual opening and closing of injectors are not the same as indicated by the injection command due to the injector delays. Two sets of injection test benches (an EFS injection test bench and a Bosch style long tube) are set up in the Clean Combustion Engine Lab. They can be used to measure shot to shot injection quantity and the rate of injection profile. With the information, together with the timing and duration of the injection command , the injector opening and closing delay can be determined. The results provide critical information to evaluate the performance of injectors. Moreover, the data is important for the research of the in-cylinder injection and the subsequent combustion process.

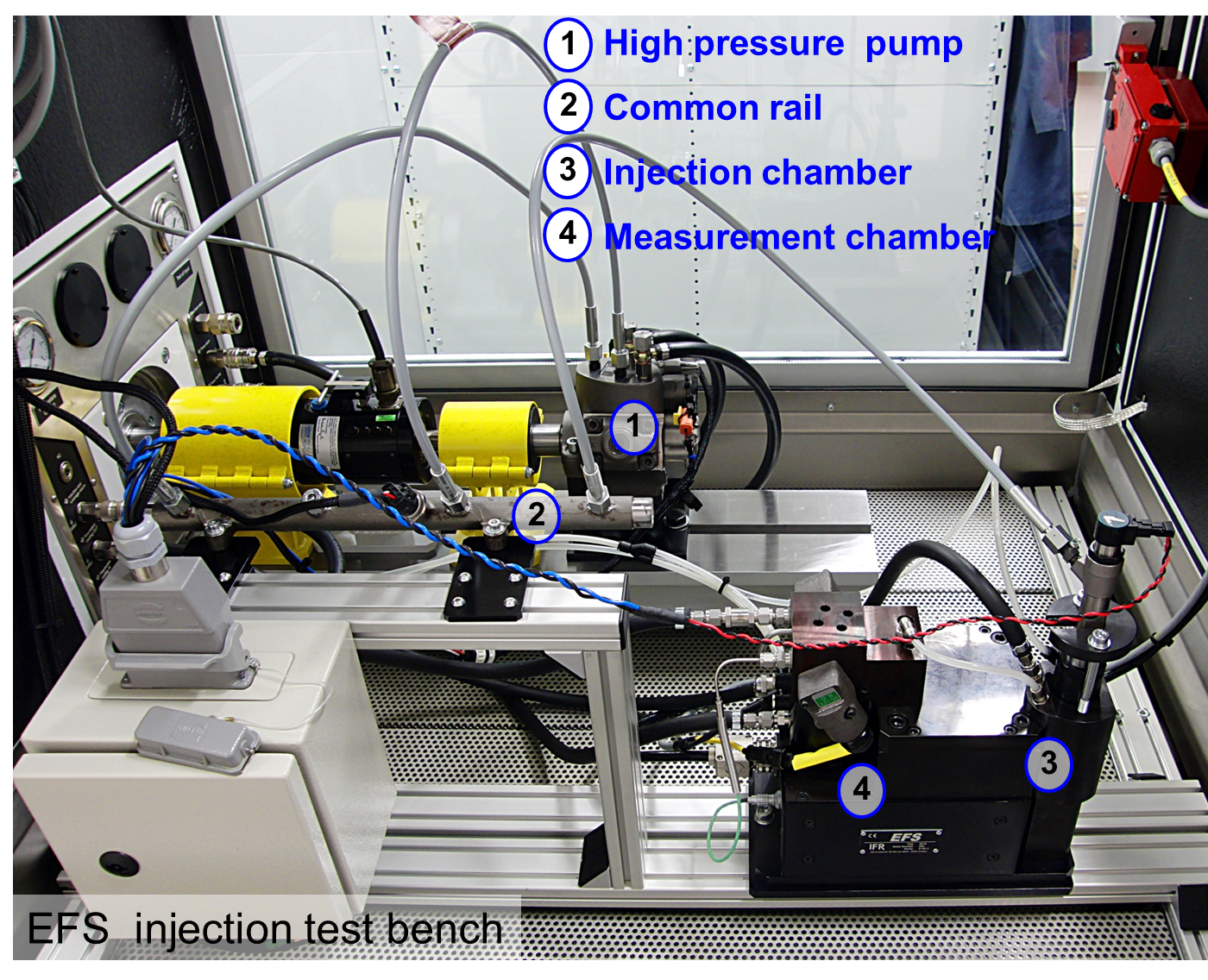

EFS Injection Test Bench

The EFS injection test bench is used to icalibrate the injection rate and perform the fuel strategy feasibility tests for single/multiple-shot fuel injections.

| Specifications | |

|---|---|

| Injection pressure | 50 - 1800 bar |

| Background pressure | 5 - 100 bar |

| Injection frequency | 0.5 - 5 Hz |

| Measurement accuracy | 0.2 mg/cycle |

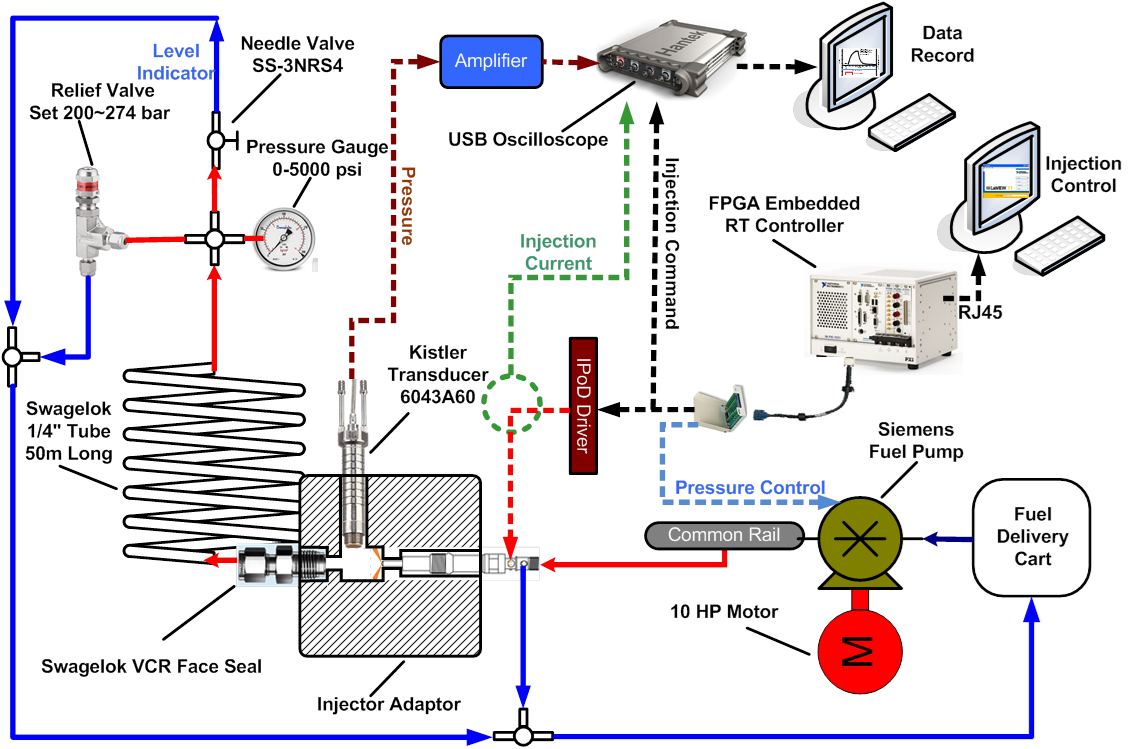

Bosch Long Tube

An in-house made long tube injection test bench is another system that can be used to test the performance of high pressure injectors. The long tube test bench consists of a very small injection chamber connected with a 50 meter long coiled stainless steel tube. A pressure sensor is mounted on the injection chamber to measure the pressure. When an injection is commanded, the pressure in the injection chamber increases. Since the injected volume is theoretically proportional to the dynamic pressure (W. Bosch, 1966), the injection volume can be calculated from the pressure change.