Back to Lab Facilities

AVL Single cylinder heavy duty research engine

The AVL single cylinder research engine is set up for engine combustion research under challenging conditions. It is a customized engine with a displacement volume of 2.07 L. The major components of the engine are specially designed to meet the requirement of in-cylinder pressures (up to 300 bar). The engine is currently connected with an alternating current (AC) dynamometer rated at 600 HP. The engine has two cylinder heads, one of which has the capability of in-cylinder optical accessn. Two access ports are reserved on the cylinder head for AVL VisioScope system which enable the cylinder viewing during combustion events. The high-speed camera system with an intensifier is capable of directly capturing the in-cylinder fuel injection and combustion processes. A fuel injection port on the intake pipe can be used for port fuel injection for dual-fueling research. These configurations enable the in-cylinder combustion research with a variety of fuel combinations under high load conditions.

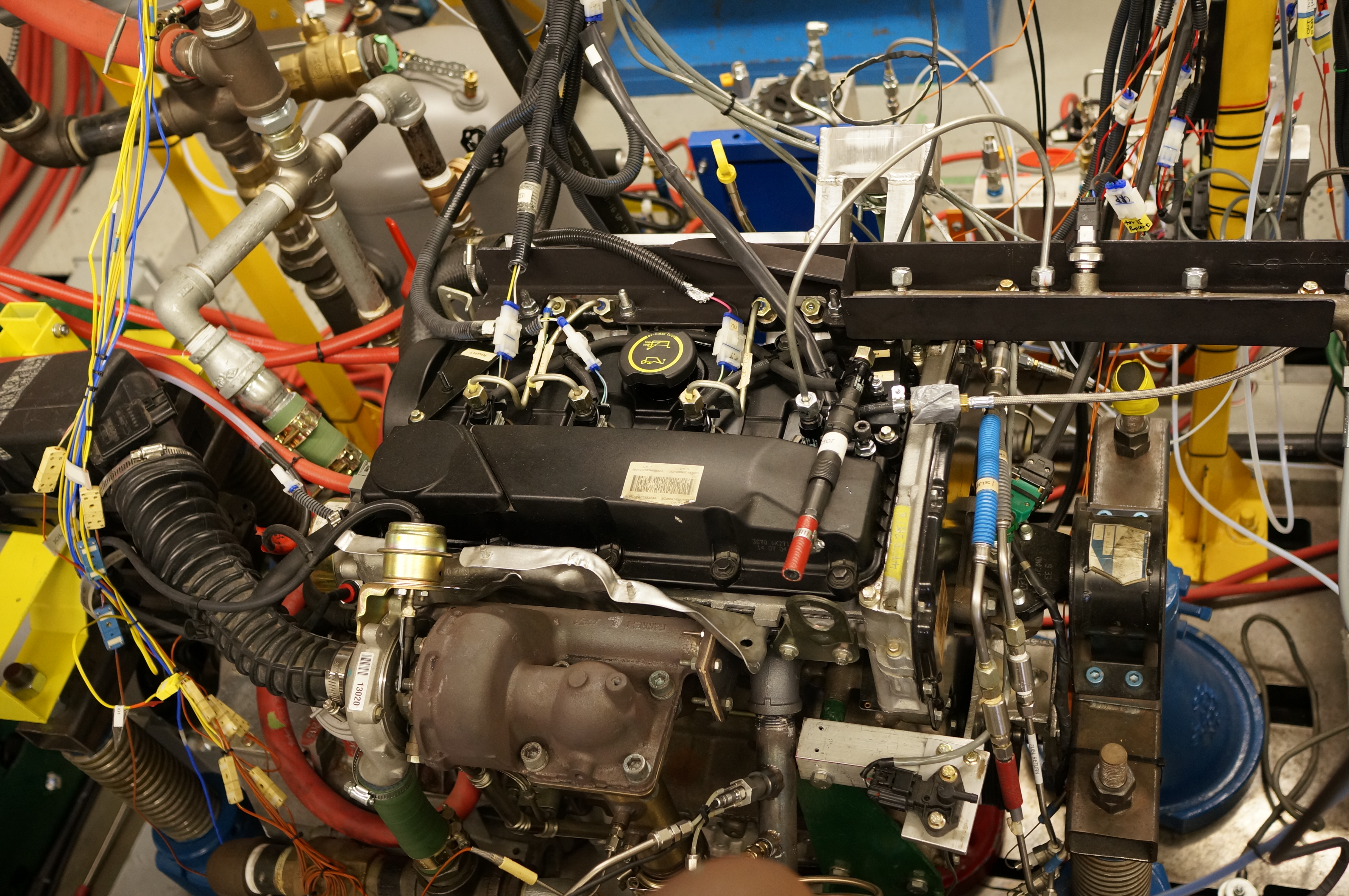

Ford Duratorq research engine

The Ford Duratorq diesel engine is a four cylinder production engine modified to run as a single cylinder research engine. The first cylinder is isolated from the other three and connected with independent fuel and air supply systems. The engine is coupled to a 300 HP eddy current dynamometer. The intake port of the first cylinder is equipped with two gasoline-type port fuel injectors. The original ECU of the engine is replaced by in-house built control systems which have full control of the research cylinder (as well as independant EGR control, injection control, backpressure control, boost, PCV, VCV, sensor and emission monitoring). This modification provides high flexibility in running engine tests. This engine has been used intensively in low temperature combustion research and alternative fuel research. The lubricant and coolant are independantly conditioned through FEV LubCon and CoolCon systems.

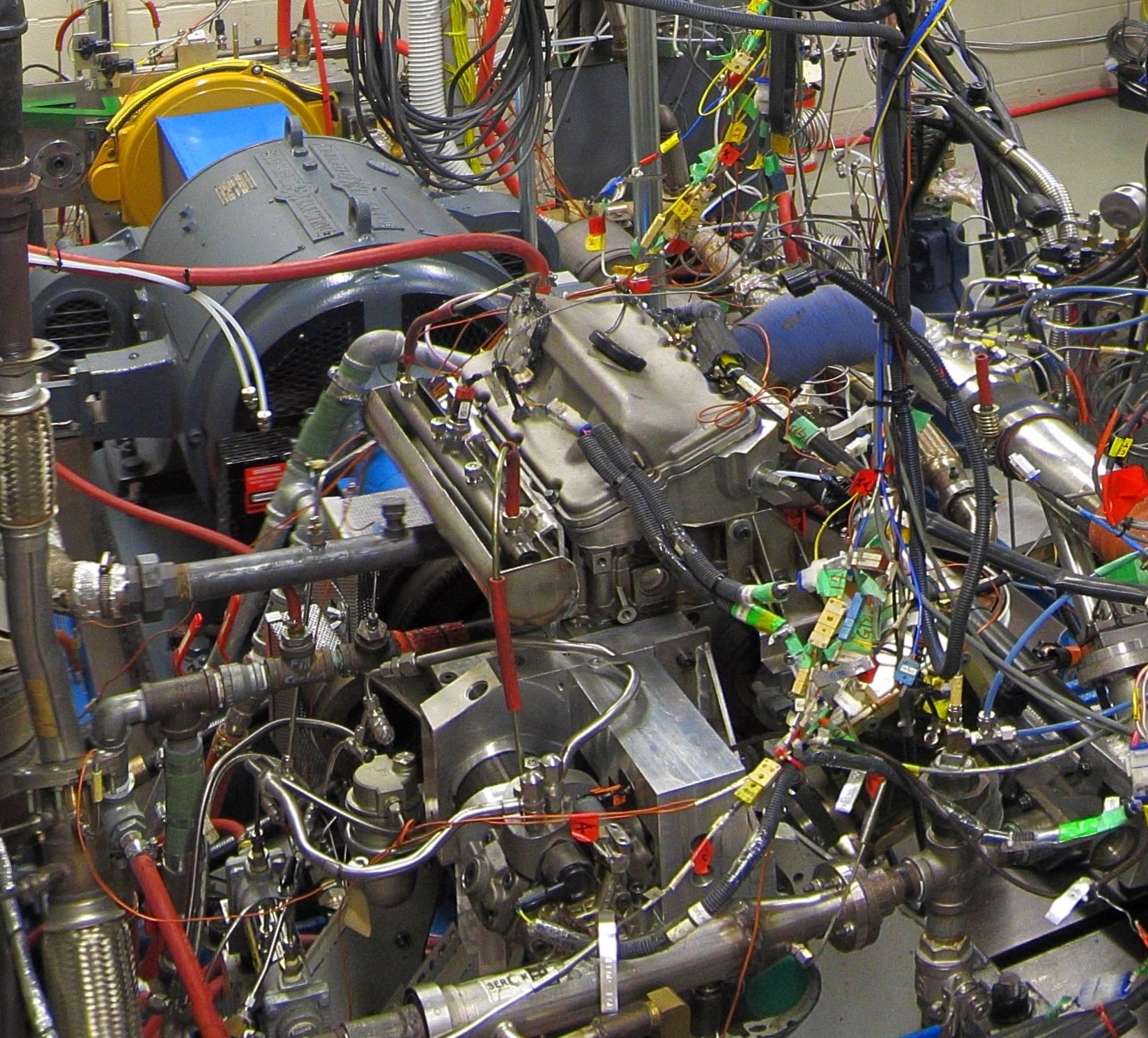

FEV and Yanmar single cylinder research engines

The FEV single cylinder research engine and Yanmar NFD 170 engine are connected to a 40 hp direct current (DC) double-ended motoring engine dynamometer. The FEV engine has a research single cylinder block mated to a production cylinder head. Customized pistons can be used in this research cylinder. The research conducted on this engine includes combustion chamber shape studies, compression ratio variations studies and fuel impact studies.

The Yanmar engine was originally a stationary production diesel engine which has been modified for combustion research. The two-valve design facilitates modification of the cylinder head for additional instrumentation such as in-cylinder direct gas sampling and spark plug mounting.

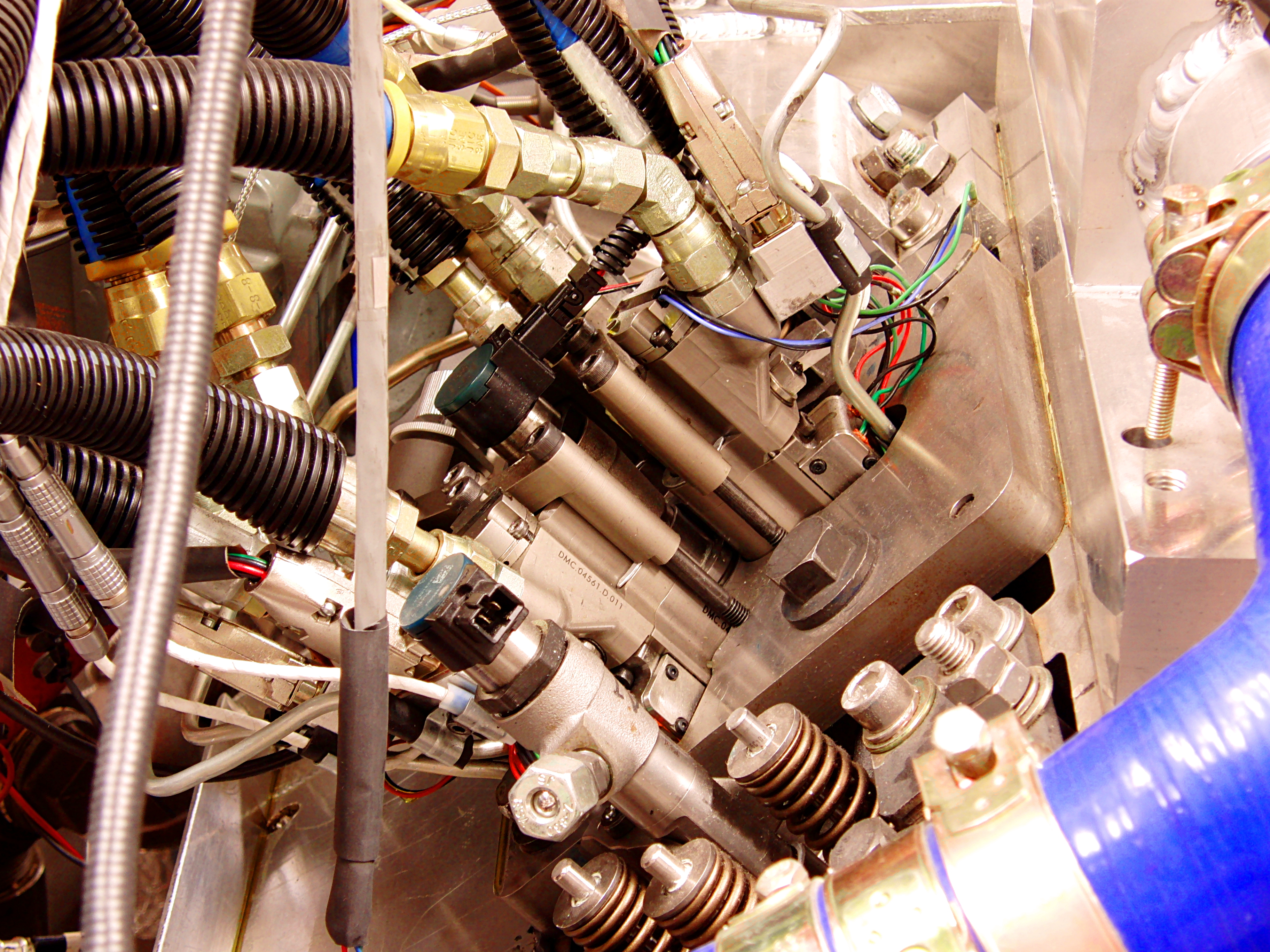

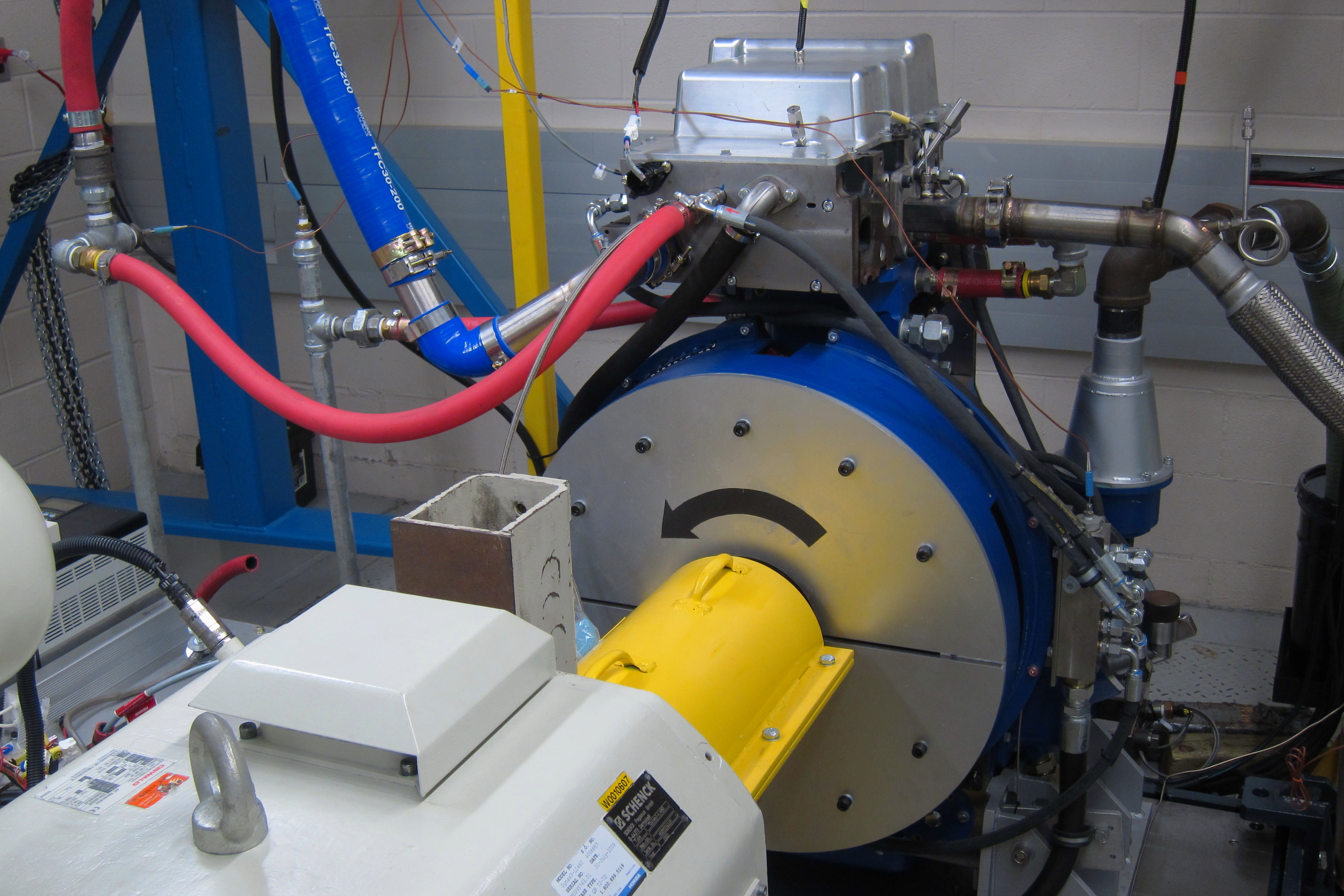

Medium duty V6 diesel engine with Sturman fully variable valve actuation

A medium duty V6 diesel engine was modified to run as a single cylinder research engine with fully variable valve actuation and coupled with an eddy current dynamometer. The research cylinder has hydraulically operated intake and exhaust valves that allow fully independent valve actions. Each one of the four valves (two intake and two exhaust valves) can be controlled independently for timing and lift. The valves can be opened twice every engine cycle to facilitate for example exhaust gas trapping or rebreathing.